For a more detailed explanation of the backpack design process, please go to the Backpack 2.0 Page. The main goal of this backpack prototype was a proof of concept to make sure my backpack pattern would come together properly to produce the extremely capable backpack that I had designed. I used very cheap fabric from Walmart to construct the prototype, with the main fabric being some vinyl coated stretchy fabric, and the "mesh/3D mesh" being a very thin, somewhat stretchy, extremely breathable fabric. Most of the webbing was sourced from other old packs or from a ratchet strap. The grosgrain and zippers were also a Walmart special. The hardware was mostly 3D printed from PLA, and some being printed with PETG to prototype print settings for the final version of the backpack. Again, the design process of the hardware will be covered on the 3D Printed Hardware page. Overall, the completion of this pack taught my important aspects of the sewing and construction process, and provided me valuable insight for constructing the "Backpack 2.0". It held up to a field test, and provided me ideas of where the future design could be improved for further usability.

For Prototype, read:

3D Mesh, Spacer Mesh, Duraweave = Blue Fabric

X-Pac = Red/Black Fabric

1. Shoulder Straps: Trace materials, 3D mesh for back, foam for inserts, teal X-Pac for three outer segments, Duraweave for pockets, D ring for InReach side carabiner, some sort of webbing set up for the bear spray side. Follow the shoulder strap guide to make the straps. Make sure to attach webbing to the middle pieces for the sternum strap, webbing to the top, boxed at about 6-7.5 inches under the top of the top piece for the load lifters, and about 3-4 inches of webbing on the bottom piece with a ladder lock attached. Shoulder Strap Guide

2. Hip Belt Frame Bottom Stop Assembly: Sew shoulder strap webbing onto hip belt back panel first at a slight angle, see pics (Wrong order on Prototype, RED WEBBING). Sew frame bottom stop together with webbing and then sew onto hip belt back panel. See this guide to reference the frame bottom stop webbing assembly. To sew this assembly you need two pieces of 1 inch webbing, one piece 7 inches long and the other 20 inches to 2 feet for each side. See photos for the detailed assembly, make sure it is extremely reinforced, as the frame will carry most of the forces on the pack to this location. With the 7 inch piece leave a 1 inch section at the top and bottom to x box sew onto the back hip belt panel, and leave a bit of slack on the bottom of the strap, see pics. The top apparatus of the frame attachment is 2.25 inches from the sides of the back hip belt panel, and two inches down. The bottom one is installed an inch below that.

3. Hip Belt Pockets: Next, sew the hip belt pockets. Use lots of thought while doing this. First size the zipper to proper length, and sew the zipper ends on each side, probably look into a 1 inch by 1 inch square for this size. Sew these onto the zipper on the BACKSIDE, before hand make sure to put the zip on REVERSE so the pull is on the BACKSIDE. Now sew the backside of the zipper below the pocket top panel. Then sew it below the STRAIGHT PART of the Front Pocket Panel. I recommend using the proper color thread for the pocket assembly as the thread will show. Sew the bottom panel onto the front, French seams work but look bunched. Then sew the back panel to the top and the bottom, sew with the half inch seam allowance and the SEAM OUT to be sewn onto later. Make 2 pockets, and make sure they are right side and left side and oriented correctly. At the time of making the prototype, make sure the top and bottom taper together at the top and bottom with the seam allowances in there, so it doesn’t need to be pleated at all. Then once the back is sewed to top and bottom, take the half circle back part of the hip belt. Sew the 1.5 inch webbing into the seam allowance, and box it, make sure the box doesn’t go into the seam allowances on the edges, then sew the side onto the correct side of the pocket. Do with each one.

4. Finish Hip Belt: Then connect the back panel of the hip belt to the correct pockets. Before/ during this make sure to measure out the hip belt length, and make sure it will fit around you without interfering in the front!!!! After the whole back piece is sewn together sew the spacer mesh on, inside out, leaving one side unsewn, then flip right side out and then stuff the foam inside. Then sew the hip belt closed.

5. Back Panel: Sew on webbing top stop for aluminum frame so aluminum rod ends 1 inch from the top measurement (½ inch) with seam allowance on the Back Mid Panel. The frame will also be 1.5 inches in from each side of the bag (Remember ½ inch seam allowance on sides as well). These are on the Back Bottom Panel. Use 1.5 inch webbing, and fold it over to prevent the fabric from abrasion. Sew a channel to keep the frame straight 7.5 inches up from the bottom of that panel and also 1.5 inches in. Also sew another channel .75 inches from the bottom of the panel at 1.5 inches in. Use webbing for these as well, and think about using folded over webbing to possibly prevent abrasion. Use 4 inches of webbing and ladderlocks to sew above the top frame ends on the Back Mid Panel. On the bottom of the Back Bottom Panel, sew webbing plus ladderlocks on the bottom, two right below the frame channels, and two directly inside for the suspension. Also include webbing for the bottom of the back panel for the lateral bear canister/food bag attachment. Make sure there is at least 27 inches of webbing. Have these spaced more inside, 8 inches apart so smaller objects can be secured too. See picture

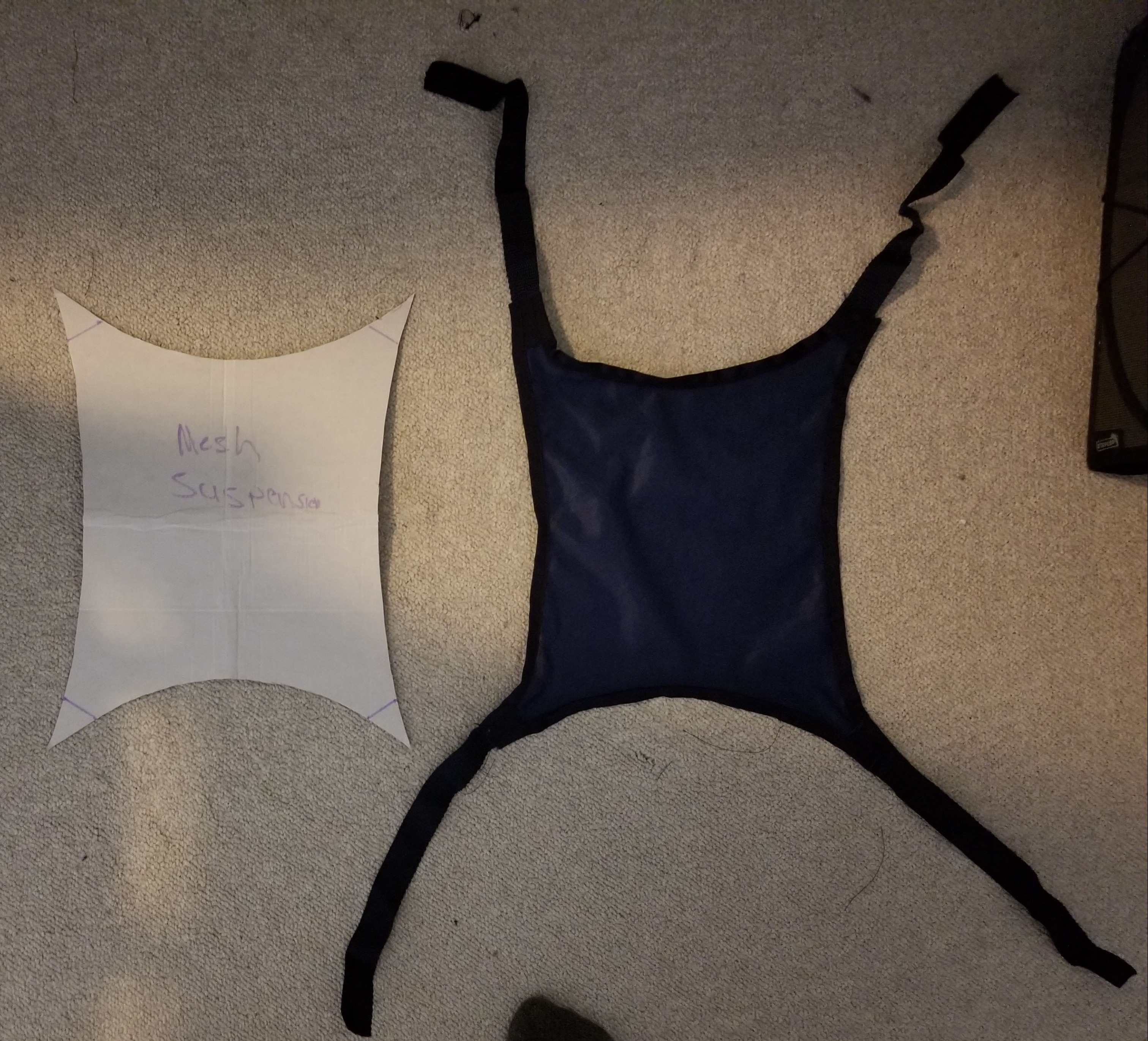

6. Suspension Mesh: Using the mesh, tape the pattern onto it and then cut out, then using four 12 inch pieces of ¾ inch webbing and four 1 inch pieces of ¾ inch grosgrain to sandwich the mesh between the webbing, sew each piece on following the picture below. Then use 1 inch grosgrain to line the edges of the mesh. This part is difficult, a binding foot helps but still messes some stuff up.

7. Shoulder Strap Back Panel Assembly: Sew some excess material over on the tops of the shoulder straps so its only foam and the shoulder straps. Clip the Bottom and Mid Back Panel together with the shoulder strap top portion sandwiched in between as pictured. Sew a French seam, be very careful and thoughtful with how it is sewn. Possibly add small relief cuts to the fabric at the tip so it doesn’t get all bunched up. Make sure where the shoulder straps connect to the back panel are extremely reinforced.

8. Back Panel Assembly: Assemble the back panel as shown, with ¾ inch webbing used for all ladder locks and webbing which are sewn on at under ¼ inch seam allowance. Once all everything is sewn on, SEE PICTURES to make sure, then sew the Top Back Panel to the Mid Back Panel. The Top Back Panel should have two ladderlocks sewn to it for the load lifters, a ladderlock sewn on for the Y-Strap adjustment, a 30 inch piece of webbing sewn on for the Y-Strap, and a Haul Loop sewn on. Sew a French Seam and be cautious of all the webbing, make sure the total seam allowance is enough to eat up all the rougher seams, and make sure that no webbing or anything else gets stuck when sewing a seam.

9. Side Panel: Use X-Pac fabric for the water bottle holder sides and then use Duraweave for the bottom portion to allow drainage of water in pockets. If it doesn’t turn out well for the prototype then using all Duraweave will be considered. Note the picture of the two different pocket sizes. Both sizes will be compared and the most effective size will be used. ALSO WHEN CUTTING THE PATTERN MAKE SURE TO FLIP THE PATTERN FOR ONE SO THE SAME SIDE OF THE FABRIC IS SHOWING ON EACH SIDE OF THE PACK. Just remember each side panel is mirrored!! First, make a channel with shock cord inside it to cinch the water bottle pockets up. Make the adjustable side of the shock cord to be adjustable from the short side of the slant. Next, sew the bottom onto the pocket. Then sew the pocket sides and then the bottom to the side panel with a ¼ inch seam allowance or under. After, sew on the buckle and webbing for the water bottles, and also sew on the shock cord loops according to the picture with ¼ inch seam allowance, which will be used for strapping on external pack items or for compression. Also sew a buckle into the bottom which will be used to longitudinally secure the bear canister/ food bag. The current idea is to use two female buckles, and then include one or two adjustable male buckles on a piece of webbing for bear canister use, or have sewn-in adjustable male buckles for the food bag addition.

10. Front Panel: Sew shock cord into the Duraweave Front Pocket. Shock cord seems to work well to allow cinching. Dimensions of the front pocket might change from the pattern currently to allow more space for things in the pocket. Then sew the front strap for the Y-Strap roll top onto the middle of the Front Panel. Sew in the middle 12 inches from the bottom of the front panel. Reinforce on the back with a small scrap piece of fabric and do a box stitch. Then stitch the Front Pocket onto the Front Panel along with loops for the shock cord. Make sure to add a loop on the bottom for the bottom part. Next sew the Bottom Front Panel to the Front Panel. Sew the female buckles onto the bottom of this following placement from the pictures, and in addition sew the bottom loops for ice axe/trekking poles.

11. Pack Assembly: Assemble each COMPLETED side panel of the pack to the back of the pack, keeping in mind the slant of the water bottle pockets faces towards the back of the pack for easier access. French seam and make sure to capture everything in the seams. Then sew the front panel onto the sides, and you should have the main area of the pack completed. Be extremely careful when sewing and make sure no loose webbing gets caught in any of the seams

12. Bottom Panel Attachment: Sew on the bottom of the pack to the rest using a French Seam. Sew each side to the bottom first, then the front, and finally the back. Make sure not to capture any loose webbing or anything in the seam. Next, flip the pack inside out and it should be almost completed!

13. Roll-Top Construction: Complete the roll-top as shown in the RSBTR Dry Bag Video. But fold the pack flat in half, cut ¾ inch webbing to size, sew into the back side of the back on the inside, fold over the webbing twice and sew, then sew the buckles onto the sides.

14. Food Bag: The Initial Food Bag design followed a cylindrical duffel bag pattern, however sewing circles sucks.

Made with Mobirise website templates